Isingeniso sikaIwindi Lesistimu ye-GKBM

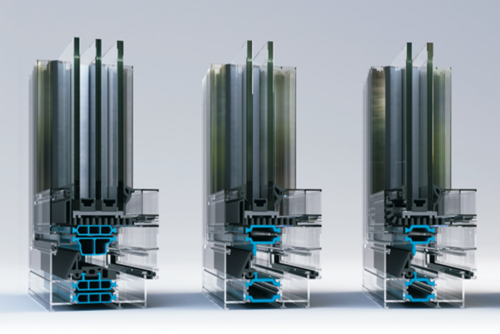

Ifasitela le-aluminium le-GKBM liyisistimu yefasitela le-casement elakhiwe futhi laklanywa ngokwezincazelo zobuchwepheshe ezifanele zezindinganiso zikazwelonke kanye nezindinganiso zomsebenzi (njenge-GB/T8748 kanye ne-JGJ 214). Ubukhulu bodonga lwephrofayili eyinhloko bungu-1.5mm, futhi lisebenzisa kusukela kuma-strips okuvikela ukushisa ohlobo lwe-CT14.8 kuya kuma-strips okuvikela ukushisa ohlobo lwe-multi-chamber 34, futhi ngokucushwa kwemininingwane ehlukene yengilazi, linemisebenzi ephelele kanye nokusebenza okuphezulu, okusebenza kakhulu ezindaweni ezibandayo.

Isakhiwo salo mkhiqizo sakhiwe ngendlela efanele, futhi ngokusebenzisa ukujwayelana kwezingxenyekazi zehadiwe nezenjoloba, izesekeli nezinto ezisizayo ochungechungeni ziguquguquka kakhulu; le nhlanganisela yomkhiqizo isebenza ngokugcwele, futhi ububanzi bokusetshenziswa kwayo buhlanganisa: ukuvulwa kwangaphakathi (ukuthululwa kwangaphakathi) njengomsebenzi oyinhloko Ifasitela elilodwa, inhlanganisela yefasitela, ifasitela lekhoneni, ifasitela le-bay, umnyango wekhishi onefasitela, ifasitela lokukhipha umoya, ifasitela lokungenisa umoya le-corridor, umnyango ophindwe kabili we-balcony oyinhloko, umnyango omncane oyisicaba we-balcony kanye neminye imikhiqizo.

Izici zeIwindi Lesistimu ye-GKBM

1. Iphrofayili isebenzisa isakhiwo esihlanganisiwe esiqhubekayo se-modular, futhi izinguquko eziqhubekayo zemigqa yokufakelwa i-insulation zifinyelela kancane kancane ukuthuthukiswa kokusebenza kokufakelwa i-thermal; kuyilapho amaphrofayili e-cavity yangaphakathi nangaphandle engashintshi, imigqomo yokufakelwa yezinhlobo ezahlukene kanye nemininingwane ihlelwe ukuze ifinyelele uchungechunge lwephrofayili oluhlukile njengo-56, 65, 70, kanye no-75.

2. Umklamo ohambisanayo ojwayelekile, yonke imikhiqizo ingahlanganiswa; uhlaka kanye nemichilo yengilazi yesashi kokubili ukuvuleka kwangaphakathi nangaphandle kujwayelekile; imichilo yengilazi yangaphakathi nangaphandle kanye nemichilo yesashi yangaphakathi nangaphandle ingahlangabezana nokusetshenziswa kochungechunge oluningi; izesekeli zepulasitiki ziyaguquguquka kakhulu; ukufakwa kwehadiwe kusebenzisa ama-notches ajwayelekile, futhi ukulungiswa kwehadiwe kuyaguquguquka kakhulu.

3. Ukusetshenziswa kwehadiwe efihliwe kunganikeza ukusebenza kokulwa nokwebiwa kwezinga le-RC1 kuya ku-RC3 kuye ngesidingo, okuthuthukisa kakhulu ukusebenza kokuvala kanye nokuphepha kweminyango namafasitela.

Ukusebenza kweIwindi Lesistimu ye-GKBM

1. Ukuqina Komoya: Ukwakheka kwesigaba sephrofayili kunikeza umkhiqizo ukuhlangana okuphezulu kokuvala kuneminyango namafasitela endabuko, futhi kusebenzisa imichilo ye-EPDM esezingeni eliphezulu kanye nama-engeli eglue akhethekile ukuqinisekisa ukuqhubeka komugqa wokuvala kanye nokuqina kwesikhathi eside komphumela wokuvala. Umoya ungafinyelela ezingeni likazwelonke elijwayelekile 7 okungenani.

2. Ukumelana nomfutho womoya: Ubuchwepheshe obuhlanganisiwe obusezingeni eliphezulu kanye nomklamo wesakhiwo othuthukisiwe wamaphrofayili, udonga lwephrofayili oluphakeme ngo-1.5mm kunezinga lamanje likazwelonke, kanye nokuhlukahluka kwezinhlobo zephrofayili yokucindezeleka kwenza kube lula ukusetshenziswa kabanzi. Isibonelo: izinhlobo ezahlukene zamaphrofayili e-brace aphakathi aqinisiwe. Kufika ezingeni lesi-8.

3. Ukufakwa kokushisa: Ukwakheka kwesakhiwo okunengqondo kanye nohlu olubanzi lwezicelo zengilazi kuhlangabezana nezidingo zenkomba yokufakwa kokushisa yezifunda eziningi.

4. Ukuqina kwamanzi: Amakhona asebenzisa inqubo yokujova yesakhiwo sokuvala esijikelezayo, inqubo yokujova isixhumi, inqubo yokujova izingcezu zekona, kanye nenqubo yokugoba engangeni manzi ye-stile ephakathi; imichilo ivalwe ngezindlela ezintathu, kanti imichilo ye-isobaric ephakathi ihlukanisa ikamelo libe yigumbi elingangeni manzi kanye negumbi elingangeni moya, okwenza ngempumelelo umgodi we-isobaric; "isimiso se-isobaric" sisetshenziselwa ukukhipha amanzi ngendlela ephumelelayo nefanele ukuze kufezwe ukuqina kwamanzi okuphezulu. Ukuqina kwamanzi kungafinyelela ezingeni kazwelonke elijwayelekile 6.

5. Ukufakwa komsindo: Isakhiwo sephrofayili esinezimbobo ezintathu, ukuqina komoya okuphezulu, ingilazi ebanzi kakhulu evumela isikhala kanye nomthamo wokuthwala, ukusebenza kokufakwa komsindo kungafinyelela ezingeni elijwayelekile likazwelonke 4.

Amafasitela esistimu ayinhlanganisela ephelele yezinhlelo zokusebenza. Kudingeka acabangele uchungechunge lwemisebenzi ebalulekile njengokuqina kwamanzi, ukuqina komoya, ukumelana nokucindezela komoya, amandla omshini, ukuvimbela ukushisa, ukuvimbela umsindo, ukulwa nokwebiwa, umthunzi welanga, ukumelana nesimo sezulu, kanye nomuzwa wokusebenza. Kudingeka futhi acabangele imiphumela ephelele yokusebenza kwesixhumanisi ngasinye semishini, amaphrofayili, izesekeli, ingilazi, izinamathiselo, kanye nezivalo. Konke lokhu kubalulekile, futhi ekugcineni kwakha amafasitela neminyango yesistimu esebenza kahle kakhulu. Ukuze uthole imininingwane eyengeziwe, chofozahttps://www.gkbmgroup.com/system-windows-doors/

Isikhathi sokuthunyelwe: Septhemba-09-2024